Graphics and content provided by Far East Facade (Hong Kong) Limited

1. Introduction: Advancing Climate Adaptation through Façade Design

At the 2021 UN Climate Summit, China pledged carbon neutrality by 2060 and a 65% emission reduction from 2005 levels. Hong Kong, as an international Chinese city, actively supports this goal.

Buildings in Hong Kong account for 90% of electricity use, with air-conditioning making up nearly a third. From 2012 to 2022, cooling loads rose while lighting loads declined, possibly due to increased use of curtain walls, which enhance daylight but increase solar heat gain.

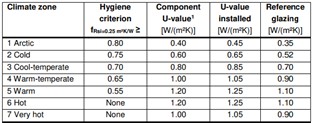

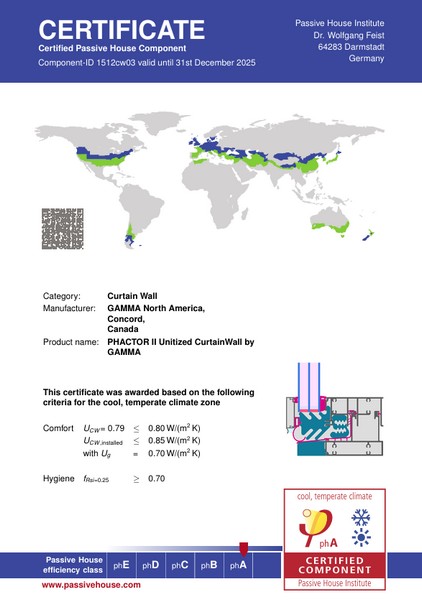

OTTV and RTTV standards are in place but give limited attention to conduction and are complex to apply. Passive House offers a performance-based framework that includes airtightness, insulation, shading, and certified components—features well-suited for high-rise cities like Hong Kong.

2. Why Passive House Matters for Hong Kong

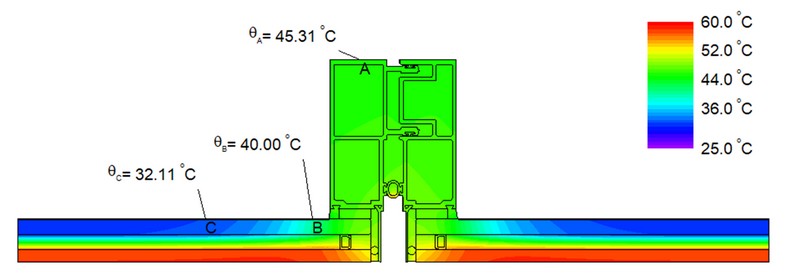

Passive House evaluates all heat transfer modes, including conduction, which is often ignored in hot, dense cities. Sun-exposed materials can reach 60–80°C, while glass surfaces can reach up to 90°C, significantly increasing cooling demand according to the Code of Practice for the Structural Use of Steel of Hong Kong 2023 edition.

Thermal simulations show that such exposure can raise interior mullion and glass edge temperatures by 40–45°C. Current Hong Kong standards lack detailed treatment of thermal bridging, whereas Passive House addresses this directly.

3. Challenges of Implementing Passive House in Hong Kong

Current codes lack focus on thermal conduction, so the industry does not feel a strong need to improve insulation or bridge design.

Thermal breaks—essential in façade systems—are not always accepted by Hong Kong’s Buildings Department, particularly interlocking types. These are not seen as mechanical fixings and require case-by-case review.

Façade projection limits and lack of structural guidance make it difficult to integrate thermal breaks in design. These barriers slow down innovation and Passive House adoption.

4. Policy and Industry Collaboration

Performance-based compliance pathways should be introduced, and projects meeting Passive House standards could receive expedited approvals or GFA bonuses.

Professional institutions should help issue structural design guidelines for thermal break systems. Manufacturers can assist by certifying components via the Passive House Institute. Pilot projects, training, and industry-academic collaboration are essential to build capability. Passive House is more than a design upgrade—it’s a shift in values toward long-term building performance.

By aligning with China’s dual carbon strategy and global best practices, Hong Kong has the opportunity not only to catch up, but to lead in resilient low-carbon development.