Designed by leading architects, P&T Group, Hong Kong’s newest sports venue, Hong Kong Velodrome (HKV), signals both recognition of the increasing international success of local elite athletes and the community’s recognition that a healthier lifestyle contributes to a long, active and productive life.

Scouring the planet for inspiration, P&T inspected velodrome facilities from China to Switzerland, noting positives and negatives in existing facilities around the world and applying inspired design plans to the city’s first dedicated elite sports training facility that also provides full community access.

Scouring the planet for inspiration, P&T inspected velodrome facilities from China to Switzerland, noting positives and negatives in existing facilities around the world and applying inspired design plans to the city’s first dedicated elite sports training facility that also provides full community access.

“P&T were very conscious of two important considerations in relation to the design and construction of HKV,” states P&T Director, Tsang Ho Yin. “The first issue related to the fact that HKV is Hong Kong’s first dedicated elite sports training facility, so there was great interest by the general public in relation to the overall design of this new facility that also aims to place Hong Kong firmly on the map of destinations around the world promoting elite sports.”

“P&T were very conscious of two important considerations in relation to the design and construction of HKV,” states P&T Director, Tsang Ho Yin. “The first issue related to the fact that HKV is Hong Kong’s first dedicated elite sports training facility, so there was great interest by the general public in relation to the overall design of this new facility that also aims to place Hong Kong firmly on the map of destinations around the world promoting elite sports.”

“The second consideration related to HKV’s location, what facilities would be provided for elite sports athletes, whether community access would be permitted and if so, what facilities would be provided to encourage greater participation in sports by the general population.”

Elaborating further, Tsang explains that in order to familiarise themselves with existing elite sports training facilities around the world, in particular those focusing on cycling, the P&T design team visited indoor velodromes including Beijing’s Laoshan Velodrome (Olympic Games 2008), Guangzhou Velodrome (Asian Games 2010), and Aigle, Switzerland (Headquarters of International Cycling Union, Union Cycliste Internationale, (UCI) and training facilities) to gain further insights on elite sports venue architectural planning, facilities layout and logistics during international events.

HKV facilities

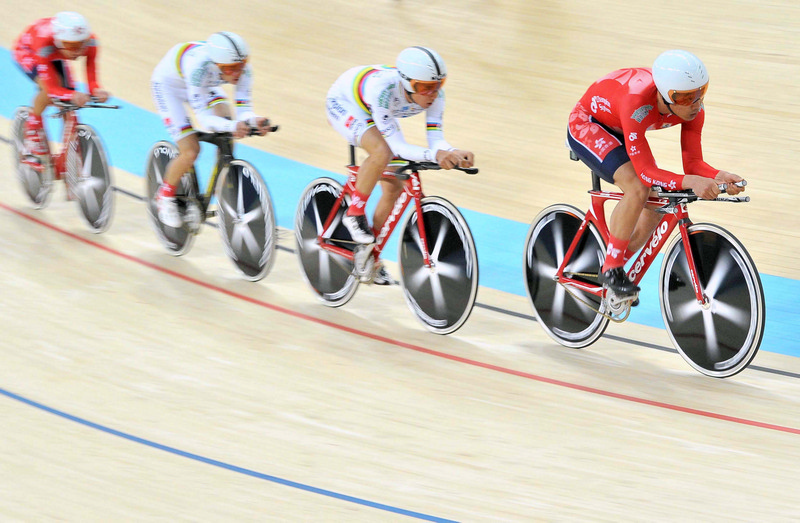

Both internally and externally, HKV provides a veritable smorgasbord of facilities for both elite athletes and the community.Specific facilities incorporated at HKV include a 250-metre long cycling track with supporting facilities meeting international competition standards; flexible spectator stand facilities, including 2,000 permanent seats and 1,000 portable seats; a multi-purpose area in the centre of the track that can be easily transformed into two basketball courts, two volleyball courts or 8 badminton courts or be used for gymnastics and other sports training; other facilities, including a fitness room, two multi-purpose activity rooms three dance rooms and a children’s playroom; and meeting rooms, a restaurant, a sports goods shop and other ancillary facilities.

Both internally and externally, HKV provides a veritable smorgasbord of facilities for both elite athletes and the community.Specific facilities incorporated at HKV include a 250-metre long cycling track with supporting facilities meeting international competition standards; flexible spectator stand facilities, including 2,000 permanent seats and 1,000 portable seats; a multi-purpose area in the centre of the track that can be easily transformed into two basketball courts, two volleyball courts or 8 badminton courts or be used for gymnastics and other sports training; other facilities, including a fitness room, two multi-purpose activity rooms three dance rooms and a children’s playroom; and meeting rooms, a restaurant, a sports goods shop and other ancillary facilities.

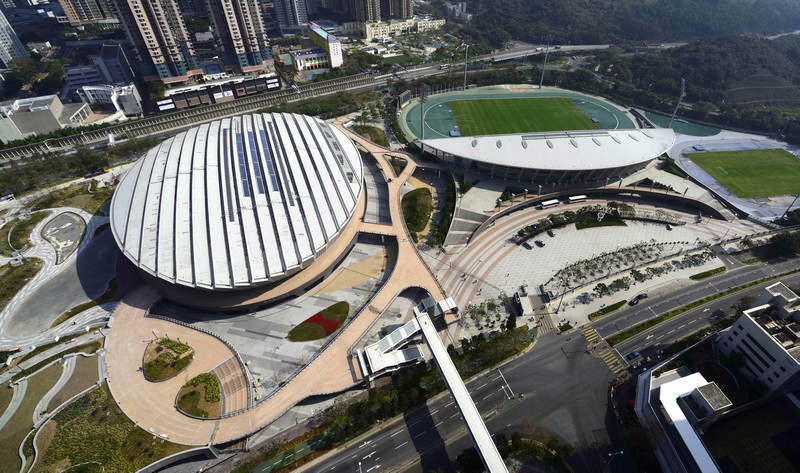

Externally, P&T also incorporated a Town Park into the surrounding areas to further promote the use of HKV facilities by the community. A lush, green open space in the centre of Tseung Kwan O, the Town Park features a garden with a large lawn area, large artificial lake, model boat racing pool, covered amphitheatre, skateboard park, jogging track with fitness training facilities, children’s play area, fitness corner for the elderly, outdoor climbing wall, and service building and other ancillary facilities.

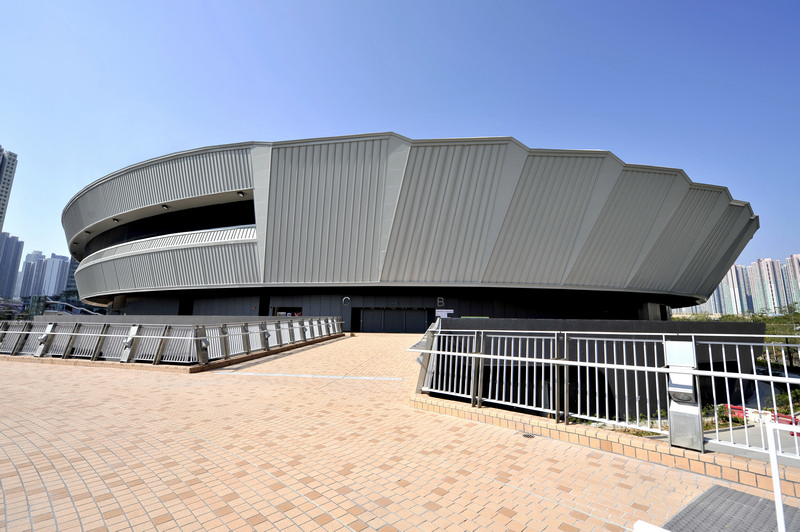

HKV roof

The oval shape metal roof at HKV spans across 150-metres at its long axis and 110-metres at its short axis. It is supported by eight sets of triangular steel trusses and a circular belt truss in the peripheral. The total weight of the supporting trusses is about 800 tonnes. The steel trusses were prefabricated in mainland China and then shipped to the waterfront of Tseung Kwan O.

The oval shape metal roof at HKV spans across 150-metres at its long axis and 110-metres at its short axis. It is supported by eight sets of triangular steel trusses and a circular belt truss in the peripheral. The total weight of the supporting trusses is about 800 tonnes. The steel trusses were prefabricated in mainland China and then shipped to the waterfront of Tseung Kwan O.

As the length of six sets of steel trusses exceeded the capacity of the delivery truck, they had to be separated into two shorter sections before being shipped to Hong Kong. To avoid affecting heavy road traffic during the daytime, the steel trusses were transported from the Tseung Kwan O waterfront to the construction site at midnight with the assistance of the Hong Kong Police Force. Using a powerful crane with a lifting capacity of 400 tonnes and other temporary supporting structures, the onsite installation work took around four months to complete. The rooftop design, drawing reference from the concept of the cyclist’s helmet, signifies a perfect synthesis of the sports element and the surrounding architecture and environment.

Cycling track

“The design and construction of any internationally accredited velodrome and its timber track have to meet Category 1 standards as dictated by the UCI,” explains Tsang. “A mock-up of the timber track was completed and inspected by the UCI in September 2011 to confirm all the design details before final installation. The mock-up was also used to testify to the performance of the timber materials and construction details under local weather conditions. The timber materials were also delivered onsite around a year in advance to allow gradual adaption to local weather conditions. For the undercarriage (track structure), we sourced Nordic Pine from Sweden and for the track surface Siberian Spruce (Pine) from Russia was used. Forrest Stewardship Council (FSC) Certification was also obtained for the wood products used to guarantee that all environmental protection requirements had been observed. Similar to other indoor velodromes, the track surface is composed of around 10,000 timber strips, with each strip section measuring around 35mm x 45mm and six-metres long.”

“The design and construction of any internationally accredited velodrome and its timber track have to meet Category 1 standards as dictated by the UCI,” explains Tsang. “A mock-up of the timber track was completed and inspected by the UCI in September 2011 to confirm all the design details before final installation. The mock-up was also used to testify to the performance of the timber materials and construction details under local weather conditions. The timber materials were also delivered onsite around a year in advance to allow gradual adaption to local weather conditions. For the undercarriage (track structure), we sourced Nordic Pine from Sweden and for the track surface Siberian Spruce (Pine) from Russia was used. Forrest Stewardship Council (FSC) Certification was also obtained for the wood products used to guarantee that all environmental protection requirements had been observed. Similar to other indoor velodromes, the track surface is composed of around 10,000 timber strips, with each strip section measuring around 35mm x 45mm and six-metres long.”

Tsang explains that the UCI has official regulations governing Track Races. The regulations outline the basic parameters of a velodrome track (geometry, length, width, profile, line marking etc.) and requirements of lighting and facilities for officials.

Tsang explains that the UCI has official regulations governing Track Races. The regulations outline the basic parameters of a velodrome track (geometry, length, width, profile, line marking etc.) and requirements of lighting and facilities for officials.

“Velodromes are classified into four categories based on the technical quality and installations. The category determines the level of competition which can be organised. Velodrome designs can vary slightly in order to meet the special needs of the end users provided that the basic parameters and requirements as stipulated in UCI regulations are fulfilled. UCI shall be invited for Homologation (approval) of the velodrome. The Hong Kong Velodrome was built in accordance with to Category 1 standards, which means it can be used for Elite World Championship and Olympic Games.”

“During the design and construction stage, the P&T project team worked in close partnership with the client department, Leisure and Cultural Services Department and the major end user, Hong Kong Cycling Association to ensure that their needs were properly addressed in the project. The building services system was also carefully designed to maintain suitable indoor environmental conditions for training, competition and maintenance all year round.”

Sustainable Features

Observing the requirement for HKV to be a sustainable structure, P&T’s design incorporated a number sustainable and environmentally-friendly features into the overall design.

Observing the requirement for HKV to be a sustainable structure, P&T’s design incorporated a number sustainable and environmentally-friendly features into the overall design.

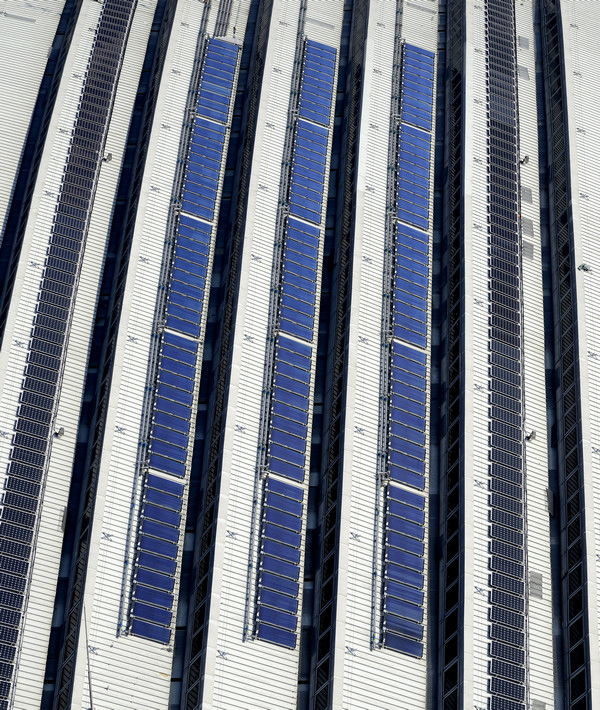

These included a rainwater harvesting system that collects rainwater from the metal roof for irrigation purpose. Rainwater will be stored at a 45m³ harvest tank which can meet 25% of daily irrigation demand. Photovoltaic panels were also installed on the metal roof and can generate up to 34,000kWhr grid-connected electricity per year. This is equivalent to a reduction of 23,800kg CO² generation and a cost saving of about HK$30,000 on electricity costs per year. Solar panels were also installed on the metal roof generating up to 153,000kWhr energy per year or energy for 80% of annual hot water consumption. It is equivalent to a reduction of 107,200kg CO² generation and a cost saving of about HK$140,000 on electricity spending per year.

Finally, the roof lights installed into the metal roof bring natural lighting into the multi-purpose arena. High efficiency, frictionless chillers were selected, together with an automated building system that continuously monitors the system’s performance to ensure optimum efficiency. As a result, reductions of up to 30% on energy use for a chiller system can be achieved.

Community considerations

P&T design director, William Yuen, states that a major consideration in relation to the design related to its impact upon the surrounding community. While elite sports facilities and even the Town Park were most welcome, the massing of the HKV building needed special design attention.

“When designing a structure, such as HKV, that is also located at the centre of an established community housed in high-rise buildings, consideration must be given to any impact the building will have upon the local community,” states Yuen. “The roof profile and colour were carefully designed to breakdown the building massing and to minimise the visual impact to the surrounding environment.”

The elliptical form and ribbed roof of the HKV building was inspired by the profile of a bicycle helmet. The curvilinear shape helps reduce the mass of the building from whichever angle you look and successfully blends into the organically shaped parkland.

The elliptical form and ribbed roof of the HKV building was inspired by the profile of a bicycle helmet. The curvilinear shape helps reduce the mass of the building from whichever angle you look and successfully blends into the organically shaped parkland.

Elevated pedestrian walkways were also designed to provide a safe pedestrian environment and to promote movement across the site. A cascading landscape deck rises from the parkland and physically connects with the Velodrome. The final result is a development destined to become a new landmark for Tseung Kwan O.