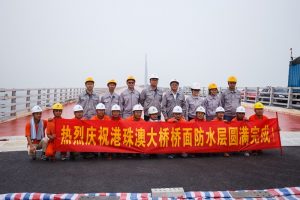

Established over 40 years ago, Stirling Lloyd is a leading UK manufacturer of high performance coatings for the protection of infrastructure and buildings. The company’s portfolio boasts some of the world’s most iconic bridges, with one of its most recent projects in Asia being the waterproofing of the Hong Kong-Zhuhai-Macau Bridge (HKZMB). Consisting of a Main Bridge in Mainland waters, boundary crossing facilities and link roads, the bridge is designed to meet the demand of passenger and freight land transport. It is also designed to establish a new land transport link between the east and west banks of the Pearl River, and to enhance the economic and sustainable development of Zhuhai in Guangdong and the Special Administrative Regions of Hong Kong and Macau.

Having conducted an extensive review and analysis of bridge deck waterproofing systems, the client, the Hong Kong- Zhuhai-Macau-Bridge Authority (HKZMBA) approved Stirling Lloyd to manufacture and supply the liquid-applied waterproofing for the three cable-stayed orthotropic steel decked marine navigation bridges.

“The HKZMB at half a million square metres is currently the largest single bridge deck job we have done. Part of the selection process was the ability to meet the capacity and tight delivery programme, as well as management aspects of the commercial, logistical, technical support and quality assurance. Our experience of waterproofing steel orthotropic bridges with Guss-asphalt (GA) and mastic-asphalt (MA) overlays in similar environmental conditions certainly helped provide reassurance to the HKZMBA,” notes Carl Pearse, Regional Manager, APAC, for Stirling Lloyd.

Winning system

On the company’s ‘Eliminator’ Bridge Deck Waterproofing system, Pearse explains how all components are based on the company’s unique ‘Esselac’ resin technology, which protects against corrosion and contributes to achieving a minimum 120-year design life. Firstly, an anti-corrosion metal primer is applied to the steel deck, before the ‘Eliminator’ spray is applied in two colour-coded coats, followed by a special tack coat designed to bond the hot poured asphalt. The system, he says, copes with the initial laying temperature of around 230 °C and creates strong bonding between the asphalt layer, waterproofing and the deck, and reduces stress over welds and joints. This allows the surfacing system to work in composite action, allowing loads and movements to be transmitted effectively.

The waterproofing process has multiple stages, the first being to remove any shop primer and rust to reveal bright steel to the specified profile. Any sharp edges, high points or fettling are then ground down. On the main decks, due to the sheer scale of the project, this was done using the largest driven ‘Blastrac’ machines available. The surface profile, or nap, is then verified through quality control tests immediately before the ‘Zed S94’ primer is applied (in the case of the HKZMB by roller) to prevent the steel from rusting. Priming also works to enhance the strong bond of the subsequent Eliminator membrane, a fast curing flexible resin, which with the warm local temperatures, hardens with minutes and becomes fully cured within just thirty minutes.

Patented quality control

While no project is without its challenges, Stirling Lloyd leaves no stone unturned when it comes to quality control.

As Pearse explains: “During application, key environmental parameters are continually monitored to ensure that the system is applied to our patented quality control system. Using airless spray pumps, the detailed central areas and edges were sprayed by hand, and due to the demanding job scale and programme, the main deck areas where sprayed using automated spray machines. The specialist applicators were audited, trained and certified by Stirling Lloyd, and our UKbased engineering technicians were sent out for training and inspection at various critical milestones before and during the works, including routine site support. The experienced technicians also worked closely with the applicators in providing practical support to optimise pump performance and wastage control.

Once pre-adhesion quality control checks have been conducted, the distinctive yellow first coat of Eliminator membrane is applied to form the minimum thickness. As Eliminator gels after a few minutes, it’s easy to constantly monitor the wet film thickness (WFT) to ensure correlation to the specified dry film thickness, thereby eliminating destructive checking tests. Once the first yellow membrane layer has been checked for any defects or damage, the second white membrane is applied. Two layers are better than one, providing extra protection against any pinholes invisible to the naked eye, enabling better quality control and ensuring an even thickness.

The cured membrane surface, which is UV resistant, is then scanned electronically using a Holiday tester to detect any discontinuities or low spots, which are then marked for repair. There was no pin-holing and hardly any snagging to do on this job. The membrane can be trafficked directly, if necessary, after just one hour. The final stage is the application of a thin red layer of tack coat to the membrane. ‘Tack Coat No. 2’ cures quickly, and, with its hard surface, is suited to the wheel loads of the asphalt paving plant. When the hot-poured asphalt is applied directly to this heat-activated tack coat, a strong chemical bond is formed, allowing the whole surface pavement system to work compositely in transmitting and dissipating the considerable stresses and strains induced by traffic loading and structural movements.”

Partnership and growth

Stirling Lloyd’s close collaboration with the client, HKZMBA, in considering and addressing the many technical and application issues, involved Pearse and his team working alongside many of the Authority’s departments, including design, operations, commercial and legal.

“We found the HKZMBA, paving contractors and inspection authorities all to be absolutely professional and highly motivated organisations, with excellent engineering knowledge and commitment to the quality and success of the project. There was a genuine spirit of partnership, and the typical challenges and problems encountered were always solved in an open and pragmatic way. Our own Production and Logistics teams in the UK likewise stepped up to the challenge. I have been in China for over 20 years but have learned a lot more during this project about doing business in the Mainland. Through the odyssey of this special job I feel I have made some lifelong contacts and friendships.”

As Stirling Lloyd continues to grow in the region, the future looks bright. Following record growth and sales over the last couple of track years, the company was recently acquired by a leading global provider of construction chemicals and products, GCP Applied Technologies Inc. Success breeds success, and Stirling Lloyd has already secured, via competitive tender, another large bridge in Anhui, China, with one of the paving contractors fresh from HKZMB.

“We are delighted that GPC’s standing and resources is already bringing us greater market coverage and penetration, along with the extra value we can now provide in terms of technology solutions and service to existing and new clients,” Pearse concludes.