Lee Garden Eight, is a JV commercial property development by Hysan Development Company and Chinachem Group. Guided by Hysan’s Community Business Model, the project prioritizes social well-being, liveability, strict environmental management standards, and positive economic impact, with the aim of creating a vibrant, resilient, and sustainable community.

(按此瀏覽中文版)

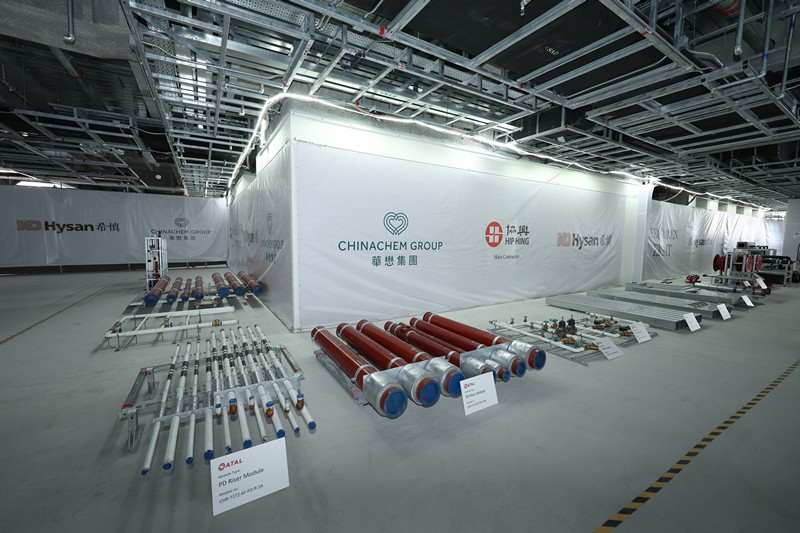

As the first large-scale private development project in Hong Kong with a high adoption of MiMEP for the “Four Trades”—ventilation and air-conditioning, fire services, plumbing and drainage, and electrical systems—Lee Garden Eight sets a new benchmark in sustainable construction, advancing its vision for sustainable development.

The project located on 8 Caroline Hill Road, Causeway Bay, with the site area 14,800 square metres, three towers from 16 to 25 floor, total GFA approximately 102,200 square metres expected to be completed at Q2 2026.

Distant Tower Crane Command System

Hip Hing Construction has implemented the innovative Distant Tower Crane Command System in the Lee Garden Eight project. This state-of-the-art system seamlessly integrates Modular Integrated Construction (MiC), Artificial Intelligence (AI), and Internet of Things (IoT) technologies, enhancing construction site safety and improving working conditions with an aim to attract more talents to join the construction industry.

Traditional tower crane operators face safety risks when working at heights and need to work in high-altitude and confined spaces for long working hours, encountering physiological needs such as using the restroom and having meal breaks. The industry is also experiencing labour shortages as well as an aging workforce. To effectively address these challenges, Hip Hing Construction developed the Distant Tower Crane Command System. This advanced solution allows operators to remotely control tower cranes from the safety and comfort of a ground-based control cabin.

With real-time monitoring technology, operators can access critical data such as wind speed and load weight, and operate cranes via remote-control equipment. By operating the crane remotely, the system can significantly reduce the risks associated with working at heights and improve working conditions.

The system is equipped with advanced multi-angle HD cameras, AI-assisted vision, and collision detection capabilities, recreating the operational environment of a tower crane within the ground-level control cabin. It enables operators to execute precise lifting operations and conduct real-time safety evaluations.

Furthermore, IoT technology facilitates real-time monitoring and cloud-based management of crane operation data, while big data analytics provide valuable insights for construction decision-making, AI-powered machine learning, and automated system development. Remote system updates and troubleshooting capabilities further ensure operational efficiency and compatibility with future advancements in technology. This innovation represents a significant milestone, laying the foundation for the future of smart construction.

MiMEP

Hysan and its project consultants ATAL, dedicated over two years to extensive planning and research to explore the feasibility of MiMEP (Multi-trade Integrated Mechanical, Electrical and Plumbing). During this process, feedback from contractors was carefully considered, and potential challenges in implementation were addressed. Advanced digital tools, including Building Information Modelling and Design for Manufacture and Assembly (DfMA), were employed to develop a comprehensive and precise master plan.

From the initial planning phase, great emphasis was placed on the manufacturability and assemblability of the “Four Trades” components to ensure efficient production and assembly. These considerations were explicitly outlined in the main and subcontract agreements to ensure clarity in the division of labour and scope of work, enabling the maximum application of MiMEP in this project. Hysan has recently restructured and adjusted its procurement strategy, ranging from tendering process to payment methods, to address challenges posed by subcontractors in adopting MiMEP, such as customs clearance, taxation, and cash flow.