[Hong Kong • 11 JULY 2025] To accelerate the application of robotic technologies in the construction sector, the Construction Industry Council (CIC) organises the inaugural Construction Robot Competition and Exhibition this year, and the “Construction Robot Practical Competition” kicked off a series of exciting activities.

Group photo of Judges and participating robot companies at the Construction Robot Practical Competition

24 robots from 24 companies participated in the Competition, demonstrating construction efficiency, safety and productivity. The finals of the “Construction Robot Challenge” brought together 12 outstanding teams from secondary schools. Selected robots from the two competitions will participate in an Exhibition at the Xiqu Centre in the West Kowloon Cultural District from 31 July to 2 August, showcasing cutting-edge robotic technologies and promoting exchanges and collaborations among industry leaders, academics, stakeholders and the general public.

Under the advisory of the Development Bureau of the Hong Kong Special Administrative Region Government and the Department of Housing and Urban-Rural Development of Guangdong Province, and with the Guangdong-Hong Kong-Macao Intelligent Construction Industry Development Alliance as the Mainland organiser, and the CIC as the organiser, the first Guangdong-Hong Kong-Macau Construction Robotics Competition was held in the mainland.

As the opening event in Hong Kong, the Construction Robot Practical Competition on July 9, which was held at the HKIC – San Tin Training Ground, featured six robotics disciplines: Drilling Robot, Welding Robot, Material Transport Robot, Painting Robot, Construction Robot Dog and Construction Drone. The 24 participating robots came from companies in the Mainland and Hong Kong. They demonstrated their efficiency, safety, adaptability and technological advancement through the completion of construction tasks, as well as their ability to be applied in critical construction processes.

Group photo of judges, guests and 12 school teams at the Construction Robot Challenge

Fostering Robot Application for Industry Transformation

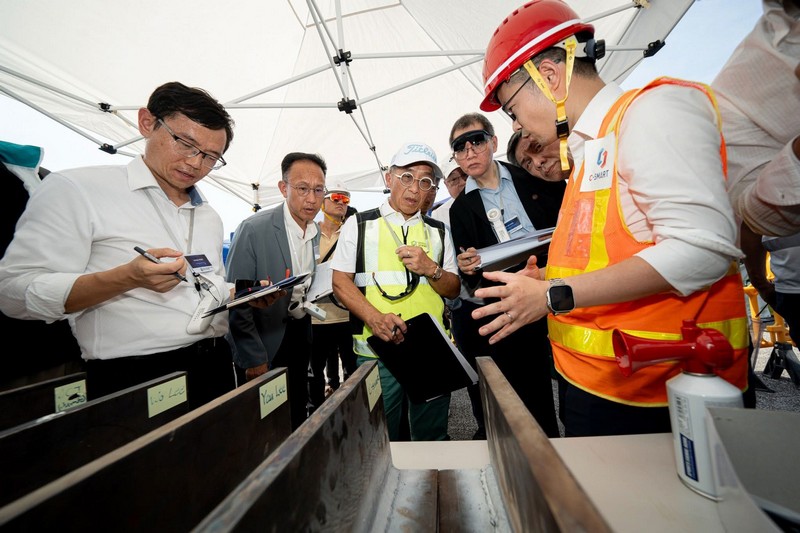

The judging panel was composed of government representatives and professionals from different fields of the industry. The competition not only highlights the rapid development of construction robotics technology and provides an industry benchmark for developers, but also promotes exchanges and collaboration within the industry, and provides an opportunity to showcase the performance of robotic products and explore business opportunities. Ir Prof. Thomas HO, Chairman of the CIC, said at the event, ‘This competition is around the core philosophy of “Proving True Skill in Practical,” aiming to establish a professional platform where robotic systems with similar functionalities can compete in a simulated construction environment. This fosters technological breakthroughs and industry innovation.’

Another highlight of the event was the Construction Robot Challenge. The event attracted a total of 14 school teams, which had to design a robotic system to perform specific operations related to construction sites. 12 teams shortlisted participated in the second stage at held on 10 July at CIC-Zero Carbon Park. They were required to create and program a robotic system using the robotic system provided by the organiser or pre-prepared by themselves to complete the pre-determined seven construction site related challenges, including walk through a slope, navigate stairs, pick up rubbish and deposit it in a rubbish box, take photo of a construction defect, stack boxes, navigate across obstacles and follow a curved path. The winning team will have the opportunity to showcase their robot design to the public at the Construction Robot Competition and Exhibition from July 31 to August 2, sharing the results of their efforts and creativity.

Ir Prof. Thomas HO (middle), Chairman of the CIC, judges on welding competition

The Construction Robot Competition and Exhibition will be held at the Xiqu Centre, WestK and industry professionals, researchers, investors and members of the public are welcome to attend. The programme will include a forum featuring internationally renowned robotics experts to share their experiences on the application of robotic technology in the industry, a performance competition for commercial robotic companies to showcase their innovative solutions, and interactive games for the public to participate. The three-day exhibition will showcase construction robots from more than 15 companies, demonstrating how technology can revolutionise traditional construction methods.

Website: www.cic.hk