Delivering a landmark roof: realising the vision for the Express Rail Link West Kowloon Terminus

Creating the landmark structure that is the roof of the new MTR West Kowloon Terminus Entrance Hall required the use of state-of-the-art engineering tools to realise the architect’s incredible vision for the project. Although no individual element of the project was unique, the combination of large loads, complex geometry, long spans and complex load paths all contributed to an unprecedented engineering challenge. International multidisciplinary engineering consultancy Buro Happold responded to this challenge by customising cutting edge software in order to create an overall design and documentation process that was capable of supporting the structural engineering.

Creating the form

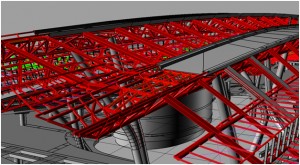

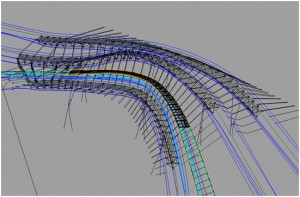

The form of the roof was established early in the design by the architects, Aedas, and it was soon realised that the roof’s distinctive free flowing form would present some unique challenges to both the analysis and the documentation process. Working flexibly with the architectural team was imperative to establish the scheme, and the necessity for close coordination of the documentation required non–standard and intelligent workflows.

The Buro Happold team responded by developing a unique set of tools early in the project that enabled a swift response to the architectural form finding. Drawing on previous project expertise these tools were developed to provide maximum flexibility with the geometry and analysis. The free form geometry required significant use of parametric modelling in order to define the structural geometry and enable analytical models to be recreated quickly as the design progressed. Linkages were established between the parametric modelling environment and the structural analysis package using programmed routines that allowed automated regeneration of the model as changes occurred through the design process.

Revit, which was used as the final documentation package, also required significant customisation in order to accommodate the highly 3D nature of the structure. Again customised linkages were formed that allowed the Revit model to be rebuilt in an automated fashion and incorporate the necessary design loops. The drawings were required to be produced in 2D Microstation, in accordance with the MTR Corporation’s CADD standards, so further routines were written to automatically create these files from the 3D Revit model, allowing the team to focus on the engineering.

Nigel Burdon, in charge of design for Buro Happold said “There was practically no way we could have achieved the deadlines without coming up with an innovative approach to the documentation process for this complex structure. As part of this strategy we were able to focus on particular elements and carry out fast optimisation loops. This not only satisfied the client, but enabled Aedas and MTR to sign off the scheme with confidence that the overall design would still achieved the architectural vision.”

Buro Happold also designed seven footbridges on the site, ranging from conventional RC decks to architecturally significant steelwork structures. Spanning up to 45m these provide essential links to the station from all sides and are an important component of the overall project.

Buro Happold also designed seven footbridges on the site, ranging from conventional RC decks to architecturally significant steelwork structures. Spanning up to 45m these provide essential links to the station from all sides and are an important component of the overall project.

Providing an effective process

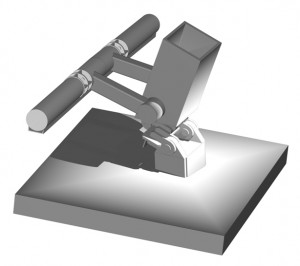

Buro Happold’s Liam Taylor, who was responsible for the technical implementation of the design tools, provides an example of the effectiveness of the process. “A good demonstration of the power of the tools developed was the design of the free-form Mega Columns. The nature of the column forms meant that they didn’t naturally respond to the high loads imposed on them. Our challenge was to intelligently tweak their geometry to derive the maximum structure benefit while still maintaining the design intent.

“By modelling these elements parametrically in 3D we were able to achieve full flexibility to make these tweaks, and the ability of the tools to regenerate the models meant that iterations could be done quickly and effectively. This resulted in highly sculptural elements which achieved the architect’s vision, were buildable, and that embody significant cost savings.”

Achieving BEAM Plus

Buro Happold’s sustainability and façade scope enabled the consultancy to leverage the 3D modelling to undertake both the thermal and lighting analysis of the huge entrance hall space. This allowed for informed selection of the glass properties to achieve cost savings and still provide the required performance for the BEAM Plus target. Glare was also assessed to ensure signage boards and critical sightlines were unaffected throughout the year.

The Revit 3D modelling also came to the fore when carrying out an embodied carbon audit of the project. Buro Happold’s automated tool for making material take-offs from the 3D model ensured accurate information to be quickly collated and presented to MTRC for benchmarking purposes. As a result of this project Buro Happold is consolidating their 3D modelling tools and has already employed them successfully on other major projects in Hong Kong and the region. The ability to link the geometry models and the analysis models together with the documentation provides a powerful platform from which to develop both complex and simple designs quickly and efficiently.

Buro Happold has developed the design from Scheme Design to Tender Documentation from their team based in Hong Kong, initially in the MTR project office and latterly from their office in Wan Chai. The project has involved dozens of staff across the organisation from UK and elsewhere and has been a truly global collaboration.