Macau’s newest leisure and entertainment resort comes to life thanks to Leighton Asia’s focus on building a strong management team. It was immediately clear that when Melco Crown Entertainment announced that they would be building City of Dreams (COD) that it was intended to be the crown jewel in the already glittering tiara that is Cotai in Macau.

The vision called for a three storey podium-style building located in the heart of Cotai in Macau – City of Dreams. City of Dreams has more than 20 restaurants and bars, offering a diverse array of dining experience and designer brand shopping in this “city-like” resort.

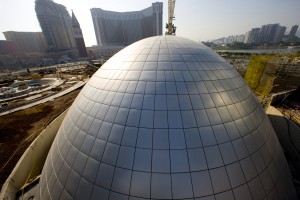

In addition, the podium would house The Boulevard, a 175,000 square feet of high-end retail space spread across two levels. On top of the podium would sit four towers, housing three hotels including Grand Hyatt Macau, Hard Rock Hotel, Crown Towers and a luxury apartment block. Finally, the project called for two state-of-the-art high definition theatre, ‘The Bubble’ and the ‘’Theatre of Dreams’ housing the Dragone inspired production.

And while COD was clearly a dream project for Melco Crown Entertainment, it was going to prove a tough challenge for the construction contractor to pull off given the scale, technical challenges and tight deadlines attached to it. This task fell to Leighton Asia to form and lead a Joint Venture with John Holland and China State, who was awarded the construction management contract.

“Construction management is relatively new in the region, with most construction companies operating on ‘hard dollar’ bids. Jobs like this are really fast track in terms of overlapping of the design, procurement and the build, so all things are compressed into an awesome overall duration,” explained Ian Edwards, executive general manager of Leighton Asia’s operations in Greater China.

“What sets us apart is that we have the ability to work closely with our clients in a spirit of partnership in pursuit of a common goal as well as our ability to source key staff with relevant experience and draw from the extensive knowledge base from within the Leighton Group.”

Nuts and bolts

From an engineering perspective the project presented a number of engineering challenges even from the onset. To prepare for construction Leighton had to manage the water table across the site to prevent pile migration, ground heave and slippage during the construction of the pile caps and the raft slab during the wet season. This was achieved by introducing a perimeter deep well cut off system, localised dewatering and layered excavation for the construction of the pile caps and raft slabs. In addition the pile caps also featured a coolant piping system to alleviate high temperatures in the concrete.

The key element here was speed and Leighton placed an estimated 115,000 cubic meters of concrete in the podium in just ten weeks, placing an enormous pressure on materials, labour and logistics in the region. All in all, 8,700 concrete and steel piles were used to prepare the raw site, which was then topped off with a 4,860 square meters of pile cap and base slab, the largest continuous pour of its type on the project.

Once the site was prepared the task of tackling the construction challenges began. Chief amongst these was the nine-level above and four-level underground theatre complex, which ran concurrently with the erection of large portal frames. In order to pull off this challenging task Leighton made use of one of the largest RMD launching trusses ever used in the region.

“The problem was that the deepest structure was the theatre, which required a deep basement to accommodate the water stages that fly out. The program dictated that we had to build the basement and structure at same time. So we had to use a top down approach, which meant using some fairly innovative structures to get the roof on and ground support for the basement,” said Edwards.

The main structures themselves involved an enormous amount of material, with 363,200 cubic meters of concrete being used, which in real terms translates to a staggering 55,000 concrete trucks. This was held together with 102,750 tonnes of reinforcement bars and 36,140 tonnes of structural steel being used in the podium. On top of this the project also used 218,000 cubic meters of metal bondek, poured 33,300 cubic meters of suspended concrete slabs in the podium and used 107,800 cubic meters of waterproofing to seal it. The building was then clad in 75,000 cubic meters of glass panelling. In addition to the construction, the COD project also required the construction of a private substation to supply the 60MVA required to power the casino-hotel resort. As such a 66KVa substation with 3 x 40MVa transformers was constructed on the premises.

The main structures themselves involved an enormous amount of material, with 363,200 cubic meters of concrete being used, which in real terms translates to a staggering 55,000 concrete trucks. This was held together with 102,750 tonnes of reinforcement bars and 36,140 tonnes of structural steel being used in the podium. On top of this the project also used 218,000 cubic meters of metal bondek, poured 33,300 cubic meters of suspended concrete slabs in the podium and used 107,800 cubic meters of waterproofing to seal it. The building was then clad in 75,000 cubic meters of glass panelling. In addition to the construction, the COD project also required the construction of a private substation to supply the 60MVA required to power the casino-hotel resort. As such a 66KVa substation with 3 x 40MVa transformers was constructed on the premises.

“The advantage for COD in this arrangement is that they have exclusive use of the substation and as such can now easily cope with any additional power demands for any future expansion of the property,” said Edwards.

Logistics

A key challenge of the build was in getting the huge amount of materials needed on the project into Macau in the first place, noted Edwards. To do this Leighton’s logistics team built a strong working relationship with the Macau Airport and Port Terminal. The net effect meant that as soon as a container or palletised shipment of materials arrived an immediate arrival notice was sent to the team in order to gain the maximum free storage time to meet the construction program for delivery arrangement. Additional storage was arranged through Pac On for materials that had exhausted their free storage time at the airport and port but were not needed on site immediately.

A key challenge of the build was in getting the huge amount of materials needed on the project into Macau in the first place, noted Edwards. To do this Leighton’s logistics team built a strong working relationship with the Macau Airport and Port Terminal. The net effect meant that as soon as a container or palletised shipment of materials arrived an immediate arrival notice was sent to the team in order to gain the maximum free storage time to meet the construction program for delivery arrangement. Additional storage was arranged through Pac On for materials that had exhausted their free storage time at the airport and port but were not needed on site immediately.

The site logistics team took over once the materials arrived on site to take them to their requisite locations, which presented its own set of challenges. The first of these was dealing with more 30 delivery jobs per day, with contractors also bringing their own materials on site as well. The complexity of their task was compounded by the changing material requirements as the build progressed, and the fact that many of the delivery routes changed constantly as COD took shape.

The key to achieving this according to Edwards was in putting together a strong management team under a capable and experienced project director.

The key to achieving this according to Edwards was in putting together a strong management team under a capable and experienced project director.

“At the end of the day it was about getting a management team together with the capacity to take on this challenge, and I think the advantage that we had was that we have huge resource in Australia that we can draw on, and so did our Joint Venture partners, John Holland and China State,” said Edwards. “It is thanks to the hard work, expertise and determination of people like project director Mark Moran that this construction project has been achieved at all, let alone within budget and on time. So, high praise for him and his team.”

This ‘umbrella’ executive consisted of over 700 people, which broke the project down into smaller more manageable portions, which then reported back to the executive management team. Regular communication sessions were held with each team being empowered to make decisions within established guidelines and in line with Leighton’s management systems. Monthly newsletters were also published to keep staff updated on project achievements as well as short term objectives and goals.

“This was a huge project which required an almost unprecedented rate of mobilisation of staff and associated support structures,” said Edwards. “Due to the ultra fast track nature of the project we also had to achieve regular monthly turnover in excess of AUS$100 million. As a precursor to this, the value of contracts awarded in a month peaked at around HK$1.5 billion.”

Another significant achievement of the management team and the project itself is that a very good safety record was maintained, a fact made more impressive when you consider that 7,000 workers were employed on site. This was done by proactively addressing safety concerns and reinforcing these with regular safety talks and the use of specific safety programs. “Working all those hours with a good safety record is a credit to all those involved and they should be proud of what they have achieved,” said Edwards.

On 1 June 2009, Macau’s newest leisure and entertainment resort opened its doors for the first time, marking a significant milestone for Melco Crown Entertainment. But while the project is undoubtedly a flagship one for them, the same applies to Leighton Asia who traditionally associated with infrastructure projects.

“We see our 34 year history in Hong Kong as being important to help us capture market share in our target markets in Asia and a project like City of Dreams goes a long way to further cement our reputation as a first class building contractor,” concluded Edwards.