The story of Craft Projects International is the story of a company that could – and did – become of one of Hong Kong’s most adventurous building sub-contractors, specialising in engineered solutions for roofs and wall cladding.

Craft has been blazing a sterling reputation in part because of the architectural qualities of its roofing contracts. To label Craft Project’s work as roofing, doesn’t do justice to the company. Craft literally helps Main Contractors build pieces of art; the startling, sweeping, curved architecture dreamed up by Architects and Engineers alike that adorns some of the most iconic buildings through the Asia-Pacific region.

“What we’re doing today was hardly even imagined by the industry 15 or 20 years ago,” says Craft Business Development Director Shane Livermore.

The “company that could” has grown rapidly from its breakthrough, high-profile contracts at the Hong Kong International Airport in the late 1990s to creating the highlight of Singapore’s Sports Hub complex, a 55,000-capacity, retractable dome over the National Stadium. The arena is nearing completion. One of the biggest roofs ever erected in Singapore, its design sits comfortably alongside the marvels of architecture built in the Lion City over the past five years.

All the while, ingenuity has been central to the company’s success. Craft uses its own unitised roofing product, based on a technology developed and refined over the years. The aluminium-clad roofs can be constructed to fit almost any specification. The unitised roofing is typically fabricated on-site – at ground level – before being hoisted into position. It’s at once an inherently speedy way to build a roof, a technique that keeps construction programmes on schedule and – significantly – workers safe.

All the while, ingenuity has been central to the company’s success. Craft uses its own unitised roofing product, based on a technology developed and refined over the years. The aluminium-clad roofs can be constructed to fit almost any specification. The unitised roofing is typically fabricated on-site – at ground level – before being hoisted into position. It’s at once an inherently speedy way to build a roof, a technique that keeps construction programmes on schedule and – significantly – workers safe.

“The difference between us and other roofing contractors in Asia is we prefabricate the unitised roofing on the ground, and either skin them with the standing seam cover on the ground or later in the air. We do that for three main reasons, safety, quality and programme,” says Livermore.

Safety drives much of what Craft does. So much so that the company has just claimed one of Hong Kong’s most important safety awards at the Construction Safety Awards held as part of the Lighthouse Club’s Annual Contractor’s Dinner in September.

The Champion Award for The Lighthouse Club, Hong Kong Occupational Safety and Health Association Safe Subcontractor Award recognises excellent safety performance in a vital part of the industry, often in the most hazardous activities. That Craft beat scaffolding companies and the builders of foundations to the top award, says a lot about the company’s safety record.

The Champion Award for The Lighthouse Club, Hong Kong Occupational Safety and Health Association Safe Subcontractor Award recognises excellent safety performance in a vital part of the industry, often in the most hazardous activities. That Craft beat scaffolding companies and the builders of foundations to the top award, says a lot about the company’s safety record.

“It’s fantastic to win the top safety award. It’s a real credit to our safety team who have helped grow our systems safely on site,” Livermore says.

“We have our own safety and environmental policies and the like because we really care about creating a safe working environment. There’s weekly safety meetings on all sites, daily site safety meetings with supervisors and subcontractors alike, all the various people and across each part of the job site. And that has eventually built up a safety culture.”

Craft’s unitised roofing system was rightly in the spotlight at the awards. The lateral thinking behind the system turns conventional roofing methods on their head. Instead of having dozens of contractors working at extreme heights and often on potentially dangerous angles, carrying materials, strapped into safety harnesses, Craft has the bulk of its workforce building a roof on the ground.

“The guys building our roofs are working pre-engineered jigs, just 300 millimetres off the ground, instead of 36 metres above ground level. Building at ground level means entire sections of roof can be installed with a tower or mobile crane in a matter of minutes, rather than hours and days in a traditional roofing project.”

Craft received the award for its work on the Hong Kong government’s Sludge Treatment Facility in the north western New Territories, a joint venture project involving Veolia Water, Leighton and John Holland JV.

Craft received the award for its work on the Hong Kong government’s Sludge Treatment Facility in the north western New Territories, a joint venture project involving Veolia Water, Leighton and John Holland JV.

“Instead of 100 workers up on the roof, 36 metres in the air, we have them on the ground. It’s much safer and there’s far less room for error.”

On the sludge treatment plant, the gull-wing-shaped roof was comprised of hundreds of angular, rectangular unitised roofing sections, each a few metres wide. Craft builds safety handrails into the sections’ open edges before they are craned into place. The following prefabricated piece is lifted into position and the seam zipped, ensuring the dangerous open edge is always secured.

The sludge treatment facility is part of the city’s efforts to to clean-up the Hong Kong sewage network, an ambitious multi-billion dollar project that has been ongoing for most of the past decade. The facility will handle up to 2,000 tonnes of sludge a day pumped in from Hong Kong’s 11 sewage treatment plants. Sludge is the colourful term for the remnants left behind after raw sewage is treated and dewatered.

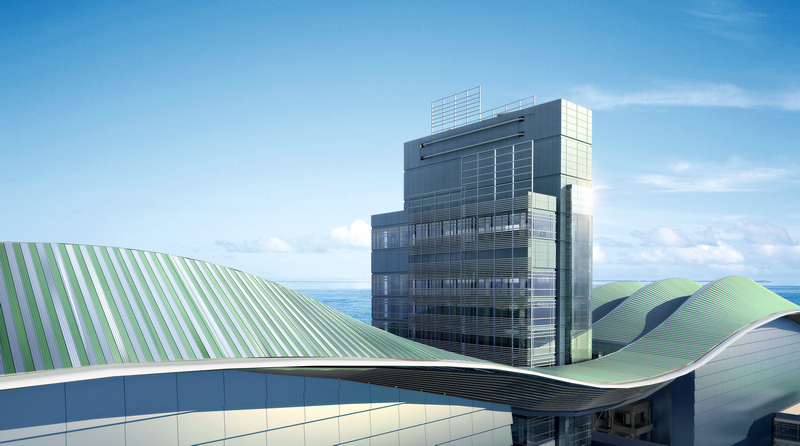

Craft has been on a growth tear, booking sales of HK$1 billion in the past three years. The company’s body of work spans everything from schools to shopping malls, industrial buildings and railway terminals. Iconic works from their portfolio includes re-roofing the Marina Bay Sands casino and resort in Singapore; the Ngong Ping 360 Cable Car in Tung Chung; and one of Asia’s biggest exhibition centres, AsiaWorld-Expo at Hong Kong’s airport in 2005.

“One advantage in the way we install our roofs is we reduce the time it takes by about a third. As soon as the steelwork is deemed safe, we’re there, installing the roof,” Livermore says.

With high-profile projects at the Hong Kong Disneyland Resort and roofing The Venetian Macao and Wynn Macau casinos behind the company, and Hong Kong’s sludge plant nearing completion, Craft has turned its ambitions to groundbreaking jobs elsewhere in the Asia-Pacific region.

With high-profile projects at the Hong Kong Disneyland Resort and roofing The Venetian Macao and Wynn Macau casinos behind the company, and Hong Kong’s sludge plant nearing completion, Craft has turned its ambitions to groundbreaking jobs elsewhere in the Asia-Pacific region.

Work is continuing on the HK$9-billion Midfield Concourse project at the Hong Kong International Airport, where Craft is installing a signature curved roof and skylights.

The company is also looking at other large projects, such as Terminal 4, the new low-cost terminal at Singapore’s Changi Airport, with a 65,000-sq-metre roof, and the Hong Kong Boundary Crossing Facilities for the Hong Kong-Zhuhai-Macau Bridge. The HK$30.4-billion project to span the Pearl River Delta is due to be completed in the second half of 2016. The roof is expected to cover an area equivalent to about 10 soccer fields.

Craft are in the hunt for a series of prestigious projects – each one more complex and curved than the next. All you need to know about Craft is this is an innovative company that can.