In a world committed to decarbonisation, PRC Magazine speaks with MAGNA Glaskeramik Plant Manager, Mr. Martin Kettmann, about why glass has become such a highly prized building material of choice.

(按此瀏覽中文版)

“Over the course of two decades in the public relations sector, I have cultivated a specialised expertise in environmental sustainability communications, particularly within the materials industry,” says Kettmann. “This focus naturally aligned with the innovative glass sector, where advancements in recycling and sustainable production have been paramount. My journey through various roles, including strategic communication planning and market research, has equipped me with the insights necessary to represent and advocate for pioneering companies like MAGNA Glaskeramik, which stands at the intersection of design, sustainability, and technology.”

Kettmann says that MAGNA Glaskeramik is distinguished by its strong commitment to sustainability, primarily through its use of recycled materials. The products are crafted from nearly 100% scrap material from industrial and bottle glass production, which can be fully recycled back into the cycle of materials after use. The production process is designed to align with the Cradle-to-Cradle (C2C) concept, ensuring continuous technical cycles and up to 80% lower CO2 emissions compared to traditional processes. Additionally, the company has been awarded the Cradle to Cradle Gold certification for its sustainable practices.

Kettmann continues, “Glaskeramik, as an interior building material, offers several benefits. It is inherently durable and creates a sense of openness and fluidity within spaces. Its reflective properties can enhance natural lighting, contributing to energy savings, and its versatility allows for a wide range of aesthetic and functional applications, from countertops to walls and lighting fixtures.”

The durability of MAGNA glass panels is implied through their sustainability and recyclability credentials, suggesting that they are designed for longevity and can be repurposed at the end of their life cycle. In terms of maintenance, the nature of glass-ceramic materials generally indicates that they are relatively easy to clean and maintain, resistant to stains, and do not require special treatments or solvents.

Expressing Brand Identity

“Translucence is indeed a significant aspect for lighting and interior designers,” Kettmann continues. “MAGNA Glaskeramik’s translucent property allows for innovative lighting effects, which can be particularly effective in brand expression. The material’s ability to be backlit creates a distinctive aesthetic that can amplify a brand’s identity through visual storytelling and atmospheric design.”

Indeed, the bespoke nature of MAGNA products means that the designs are limited only by the imagination of the designers and clients. The customisable potential of the material, given its availability in various sizes and colours, opens up a wide array of design possibilities.

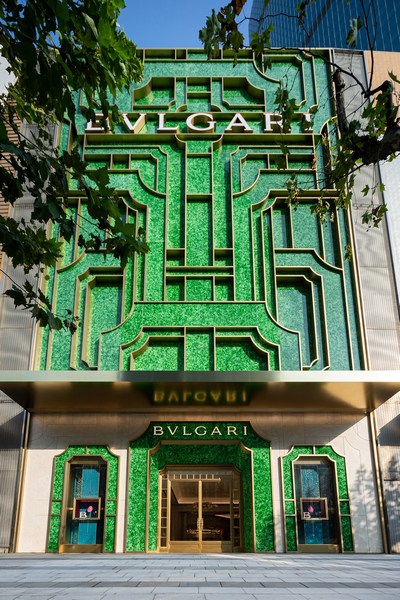

“One of the most iconic projects featuring MAGNA is with Bulgari,” he says with pride. “The high-profile nature of this partnership, along with other prestigious collaborations, underscores the brand’s commitment to quality and design excellence.” Kettmann continues, “The time from design to production to installation for key projects such as the Bulgari Shanghai Plaza 66 store varies according to different stages and processes.”

• Initial sampling was at the end of 2020. At the beginning of the project, primary samples were created to visualise the design and the desired colour variant.

• Test samples for colour variants took 1-2 months. In order to achieve the desired colour variant, intensive test trials were carried out.

• Determining the thickness of the Glaskeramik panels took around 2 weeks to determine the best variant.

• Collaboration with MVRDV: The entire process was carried out in close collaboration with MVRDV to ensure that the vision of the project was realised.

• The actual manufacturing of the MAGNA Glaskeramik slabs took approximately 4 weeks to produce the specific details and features as per the project requirements.

• Cutting the panels: Once manufactured, a further two weeks were required to cut the panels to the exact dimensions and requirements of the design.

“The Bulgari Shanghai Plaza 66 Store project is an outstanding example of a complex and complex façade cladding that combines not only design, but also sustainability and cultural references. The collaboration between MVRDV and MAGNA Glaskeramik and other partners resulted in an innovative, sustainable façade that reflects the aesthetic and environmental goals of the project.”

Myriad Applications

Kettmann says that MAGNA products are utilised for both exterior and interior applications. The company provides a variety of interior solutions such as countertops, walls, and bathrooms, as well as exterior façade panels, indicating a broad scope of applications without a stated preference for either.

Technical challenges in working with glass generally include managing its fragility during the manufacturing process and ensuring its strength and durability in application. Overcoming these challenges typically involves technological innovation in production processes and material treatments, although specific methods for MAGNA are not detailed in the available sources Beyond its sustainable attributes and design versatility, MAGNA Glaskeramik’s unique approach to material innovation is worth noting. Each product is not only environmentally conscious but also a piece of art, making it a statement choice for those looking to blend sustainability with high-end design.